Five-layer co-extrusion blown film production line

Category:

1. The host machine adopts frequency converter for stepless speed regulation control;

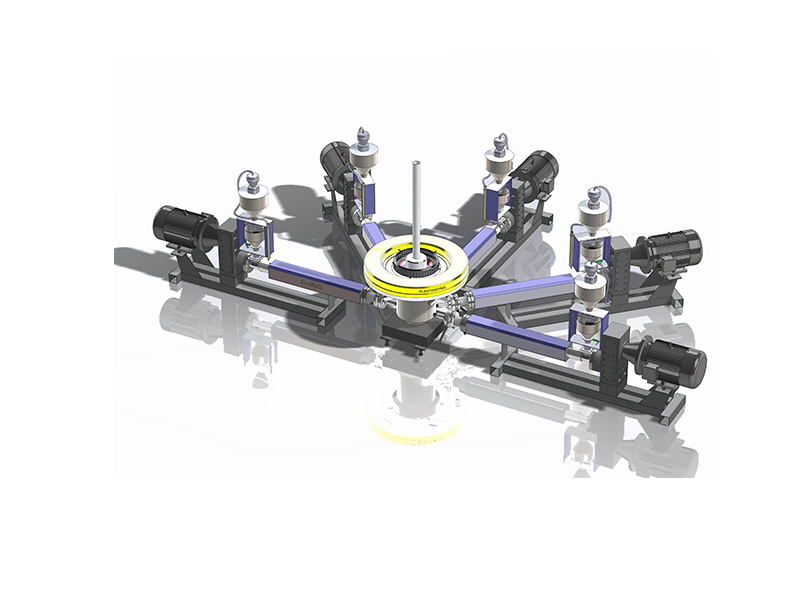

2. The die head adopts the international advanced new cone streamline superposition technology;

3. The traction system adopts horizontal ± 360 ° reciprocating rotation;

4. The IBC system uses ultrasonic to control the internal cooling of the membrane bubble, and is equipped with a new electric squirrel cage foam stabilizer;

5. Ultrasonic automatic correction device;

Tel:

Details

|

Model: |

Unit |

SGXM-1200*5 |

SGXM-1400*5 |

SGXM-1600*5 |

SGXM-1800*5 |

SGXM-2000*5 |

|

Maximum diameter of film |

mm |

1000 |

1200 |

1400 |

1600 |

1800 |

|

Membrane thickness |

mm |

0.025-0.12 |

0.025-0.12 |

0.025-0.12 |

0.025-0.12 |

0.025-0.12 |

|

Maximum output |

kg/h |

140 |

160 |

180 |

200 |

230 |

|

Mold diameter |

mm |

280 |

300 |

350 |

350 |

400 |

|

Screw diameter |

mm |

55*2+50*3 |

65*2+50*3 |

65*2+55*3 |

65*2+55*3 |

70*2+55*3 |

|

Screw length to diameter ratio |

L/D |

30;1 |

30;1 |

30;1 |

30;1 |

30;1 |

|

Screw maximum speed |

r/min |

98r\min |

98r\min |

98r\min |

98r\min |

98r\min |

|

Main motor power |

kw |

30*2+22*3 |

37*2+22*3 |

37*2+30*3 |

37*2+30*3 |

45*2+30*3 |

|

Bubble cooling method: |

Double air outlet ring + IBC bubble internal cooling system |

|||||

|

Traction speed: |

m/min |

60 |

60 |

60 |

60 |

60 |

|

Total power: |

Kw |

160 |

170 |

190 |

190 |

210 |

|

Dimensions(L*W*H) |

mm |

|

|

|

|

|

|

Weight: |

T |

|

|

|

|

|

|

Suitable raw materials |

LDPE LLDPE mPE EVA and compounding、PE |

|||||

High product quality, large capacity and low energy consumption. Our company has independently developed high-speed and high-capacity die heads by introducing and absorbing foreign advanced technology. The relationship between the melt flow rate, flow rate and the pressure in the die cavity, as well as the disturbance of the whole melt flow caused by the differential flow produced by the coextrusion of raw materials with different viscosities, were calculated mathematically.

The changes in physical means and manufacturing can minimize the pressure when the melt extrudes the die, reduce the functionality of various raw materials with different viscosities in the melt, and the melt can be extruded uniformly with undifferentiated flow to avoid melt damage. The die head has a reasonable and compact structure, accurate, short and smooth flow channel distribution, no dead corner accumulation, reduces the disturbance in the melt movement, is suitable for extrusion molding of various materials, and overcomes the flow anomalies caused by the common extrusion of a variety of materials with different viscosities. With few crystal points, the output is large, and energy consumption is low. Compared with the conventional die head, the extrusion amount is increased by about 40%.

Key word:

Film blowing production line

Traction system

Full tension control system

PLC centralized control

Message consultation

Contact number

Follow us